Friday - This afternoon, I installed the Renogy 40amp DC-DC charger including a 50amp breaker on the input side of the device. Just for future reference, the DIP switch positions I used are in the picture. Off, On, On, On, Off for Lithium batteries, 14.4V. This matches the recommendation from BattleBorn for the Renogy 40amp charger. Since there is only about 6” of wire on the output side, I used leftover 8AWG stranded wire. The input side has longer leads so I’ll use the 4AWG cables I ordered from Amazon.

Saturday - The cables and the new Magnum remote arrived yesterday while I was in the hot tub. The air temperature was 53°F so, needless to say, I was the only one there.

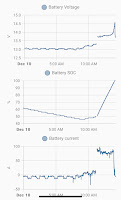

Around 11am, I switched off the main AC breaker and turned off the inverter. With the DC power still connected, per instructions, I plugged in the new remote panel. It ran through its initialization process and verified that the Magnum ME2012 was firmware v5.94. According to what I’ve read, this is sufficient to provide a CC/CV charging profile.CC/CV is Constant Current/Constant Voltage. The Magnum is now set up to provide up to 90amps until it reaches the set absorption voltage, which I set to 14.3V. At this point it switches to constant voltage and will maintain this voltage for 0.1hrs. This time is adjustable. You guess on the time to allow the batteries to get fully charged. Since the Magnum is measuring the battery voltage internally, it will read higher than actual battery voltage while charging due to resistive losses in the 2/0 cables. This is about 0.2V at 90amps. After this, the charger goes into “Silent” mode until the battery voltage drops to the “ReBulk” voltage which I have set to 13.0V. According to a table, the is about a 40% SOC which is really low. I tried 13.1V and bulk charging started at an SOC of 99%. All of these parameters are adjustable with the new remote. The short CV time and “Silent” mode are recommended as we have alternate charging options and the allows the batteries to cycle.I also have the DC-DC charger installed. I just need to run the trigger wire into the next bay and find an appropriate source. Such as the tail light. That way the coach batteries won’t be charging from the engine right after the engine is started.BTW, the hydraulic crimper does a fantastic job. This is one of the 4AWG cable for the DC-DC charger before it’s covered with heat shrink. This has been a fun project.

No comments:

Post a Comment