Thursday - Worked on the battery compartment for most of the afternoon. Two coats of Rustoleum paint and then fitted 1½” of foam around the battery holdown brackets that are welded to the bottom of the bay. A layer of 1” and a layer of ½” foam will be followed by a piece of ½” plywood that the batteries will rest on.

Friday - In the middle of the battery project, I paused to build a house. Dave, one of the work campers here, made all of the gingerbread and it was pretty tasty. Way better than the kits I usually get. But back to the battery project. I made an insulated plywood box for the batteries and sized the box to allow one more battery. The cables are 2/0 AWG welding cable. I used pocket screws to assemble the box. This is the first time I’ve used them.

I’ll use 1” rigid foam to fill in the space for the space reserved for the third battery and possibly remove everything to paint the plywood. I also need to order a main 12V shutoff switch since the relay is not functioning.

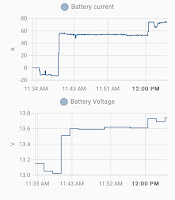

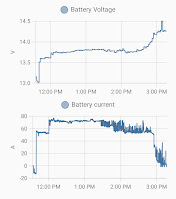

We have an older inverter, a Magnum ME2012 with a ME remote. There is no lithium battery type within settings. The “Flooded” profile has a bulk/absorption voltage of 14.6V which is at the upper end of the recommended voltage. The AGM profile is lower than recommended at 14.3V for bulk/absorption but the float voltage is way too low at 13.1V This means that the Magnum ME2012 will not fully charge the new batteries. The Victron solar controller does have a lithium profile so it'll make up the difference. I have it set to “AGM” for now but may change it to “Flooded” later.Saturday - This morning after the test session, I hooked up the batteries. After turning on the charging function of the inverter, I monitored the battery voltage on the BMV-712. I removed the Magnum battery temperature sensor as that would cause the bulk/absorption charge voltage to deviate based on temperature and raised the max output from the charger to 100amps. According to the lithium battery sites, we don’t want the temperature feature.

The project is about 75% done. I still need to install the battery cutoff switch (just ordered yesterday) and the DC-DC charger and 50amp breaker. The DC-DC charger is for charging from the engine on long drive days.

I’m also planning to paint the box and fasten it down to the bottom of the bay. Even including the box, the new system is over 150lbs lighter than the old flooded golf cart batteries and over twice the capacity. It looks like the Magnum works as advertised. It stopped charging at 14.3V. More on the Magnum later…

As always RichardM, I am awed by the level of craftmanship you bring to all project....my own efforts wouldn't look so "clean".

ReplyDeleteI was originally thinking of moving the house batteries into one of the storage bays as they would be warmer. But that would’ve required longer, larger gauge cables. Insulating and possibly heating the batteries would be cheaper.

Delete